Blog

Other Application Scenarios of Thermal Cameras

SHARE

6

May 11, 2022

The

use of thermal cameras in safety and security applications has been associated

traditionally with critical sites such as utilities, airports, or chemical

plants where monitoring human heat signatures could have significant

implications. These sensitive facilities could justify the higher costs

associated with thermal cameras since there was a need for particularly

sophisticated security systems.

Today,

the price of thermal cameras has decreased substantially while performance

continues to improve. As a result, less critical sites are also adopting

thermal systems for perimeter protection and other uses. These sites employ

thermal imagers as an early

warning system that can detect a rapid temperature increase over a short time

that could be indicative of fire. Fire can

destroy multiple buildings or installations within an extremely short time. The

value of the goods destroyed during a fire can be tremendous, and the cost of a

life that is lost during a fire is impossible to calculate. With their

non-contact method of measuring temperatures, thermal imaging cameras can

detect fires by using smoke detection or hot spot trace functions.

With

built-in temperature functionality, the camera can detect a significant rise in

temperature over a short time and issue an alarm even at long distances.

Today’s thermal cameras with their high sensitivity to temperature fluctuations

provide higher detection accuracy than standard cameras, making them particularly

fit for scenario applications such as forests, water stations, wildlife parks, fishing lakes and

other critical areas that require 24/7 monitoring like industrial parks and

warehouses. What these applications have in common is a fundamental need to

detect hot spots and detect a fire at the early stages to help prevent

significant losses.

Today’s

thermal imagers use an uncooled Vanadium Oxide (VOx) sensor that delivers

higher thermal sensitivity in a more compact and cost-effective package. Vanadium

Oxide cameras are also more reliable, as compared to other thermal imaging

technologies, due to fewer moving parts. The VOx detector offers high thermal

sensitivity (≤ 50 mK) that allows thermal cameras to distinguish among objects

in a scene with minimal temperature differences. The camera captures detailed

images where thermal contrast between object and background is minimal.

This

sensitivity to detect rapid temperature rises from far distances allows a

camera to recognize, for example, when a person uses a lighter or smokes a

cigarette, which is especially useful in highly flammable environments where

one spark could quickly ignite a fire. The rapid detection capability coupled

with built-in speakers and illuminators offers a complete early warning system

to avoid a potential fire before it starts.

Thermal

cameras, however, do not produce usable identification-level images, especially

compared to detailed color images offered by today’s visible-light cameras.

While all thermal imaging cameras contain an infrared sensor to detect infrared

wavelengths, many also incorporate a visible-light CMOS sensor that creates a

normal color image. The camera then superimposes the visible-light image over

the infrared image, providing more context and detail to the infrared image.

These hybrid thermal cameras – a single device that incorporates a thermal and

visible-light imager into one housing – address many of the safety and security

challenges for locations that are otherwise difficult to monitor.

Fuel and Chemical Manufacture and Storage

Fuel

and chemical manufacturing and storage is extremely hazardous due to the highly

flammable nature of the products. A spark from a lighter or from a lit

cigarette can quickly lead to a severe fire and cause catastrophic loss of life

and assets.

Warehouses

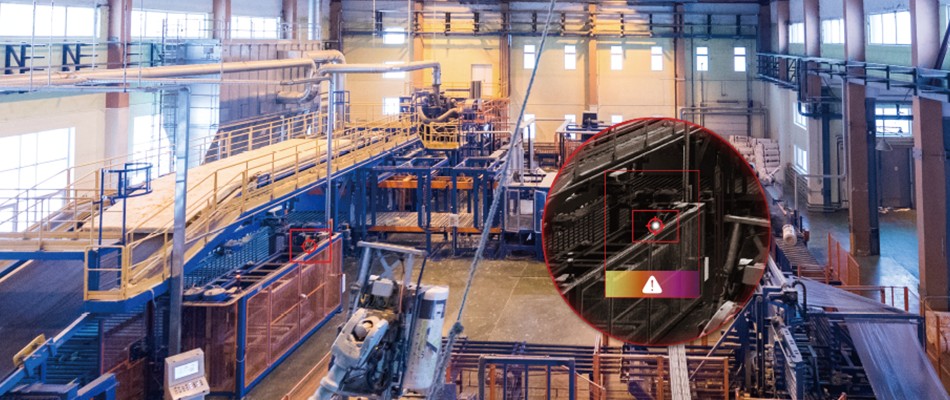

Thermal

imaging cameras can identify hot spots before they ignite and signal for an

early warning response to avoid harm to personnel or loss of assets.

Automatically monitoring temperature changes in these locations with thermal

imaging cameras can avert disaster and improve safety for workers and the

public.

Waste Management Facilities

Waste

is another potentially flammable material, especially when stored in large

piles indoors. Self-combustion, heat development due to pressure, spontaneous

chemical reactions between disposals and methane gas-buildup are all potential

fire hazards. Thermal imaging cameras can help prevent fires by identifying hot

spots with the potential to flare up.

Thermal

imaging cameras are now being used for a wide variety of applications. Thanks

to their ability to measure temperatures in a non-contact mode, many sites

employ thermal cameras as a crucial part of a complete early warning system to

help detect fires. Any industry that stores combustible or flammable materials,

any environment where flammable gases are present, and many other settings

where fires can start will benefit from a thermal camera that offers rapid

temperature rise detection.

TOPIC: