Industry Fire Prevention

Background

Pain Points

-

Lack of Early Fire Detection System

Early detection is the only way to ensure that small fires at early stage can be extinguished quickly and easily. Traditional detectors only generate an alarm when the fire, smoke or high temperature has reached the detector, which means that the fire itself has already developed and spread in the area.

-

No Visual Monitoring

After receiving a fire alarm through traditional detectors, security personnel cannot view a live video of the scene. The authenticity and status of the fire cannot be confirmed, and the possible cause of the fire cannot be obtained for evidence.

-

High-risk Smoking Behavior

Unregulated smoking behavior inside a waste transfer station poses safety risks. A lit cigarette is too small that traditional cameras and detectors cannot accurately detect it and send warning in time to deter smokers.

-

Equipment Anomalies Cannot Be Detected

Mechanical equipment (e.g. conveyer, bearing, motor, drive and pump) are prone to anomalies due to overheating. Thus, it is important to constantly monitor the quality of different machineries in the site to avoid accidents or damages. However, traditional cameras and detectors cannot detect heat and temperature of equipment.

-

Remote Location

Factories are usually located far away from urban areas, which poses challenges in terms of minimal lighting in its surrounding areas especially during bad weather conditions. Conventional cameras cannot fully achieve 24/7 intrusion detection with clear images.

Thermal Imaging for Fire Detection

Fire monitoring with infrared (thermal) systems is not fire detection, but temperature monitoring instead. Based on temperature measurement, this high-performance thermal camera can detect a potential fire hazard, such as sudden temperature rise or abnormal temperature exceeding a given threshold (e.g. 80°C). By giving early warning signals, it can help prevent occurrence of fire and allow timely response before a fire develops and spreads.

Dahua Thermal Solution Value

Early Heat Source Detection

With a pair of “thermal eyes”, Eureka Series can find what traditional cameras can't see: heat source, which can spread and become fire. It is significantly faster than a regular smoke detector alarm, especially in a relatively large space where smoke takes a long time to reach the ceiling.

Real-time Fire Alert

The Dahua Eureka series activates the alarm as soon as an abnormal temperature is detected. Combined with the built-in active deterrence system of the camera, the on-site personnel will also be notified in time through white light and audible alarm.

No Smoking Warning

Eureka Series adopts deep-learning algorithm that can identify suspicious smoking behavior by analyzing human postures and cigarette temperature. In addition, the camera uses white light and audible alarms as active deterrents to directly warn the detected smoker.

Equipment Anomalies Monitoring

Eureka series is suitable for continuous temperature monitoring of mechanical equipment to ensure safe operation. When overheating machinery is detected, an alarm will be activated and sent to relevant personnel to inform them of any possible malfunctions and fire risks.

Recommended Products

DH(I)-TPC-DF1241 / DH(I)-TPC-DF1241-T

Mini Hybrid Eyeball Camera

- Thermal resolution: 256×192

- Thermal lens: 2/3.5/7mm

- Visible resolution: 4MP

- Visible lens: 3/4/8mm

- Temperature measurement range (-T Models): -20°C to 550°C (-4°F to 1,022°F)

- Temperature measurement accuracy (-T Models): Max (±2°C, ±2%)

DH(I)-TPC-BF1241 / DH(I)-TPC-BF1241-T

Mini Hybrid Bullet Camera

- Thermal resolution: 256×192

- Thermal lens: 3.5/7/10mm

- Visible resolution: 4MP

- Visible lens: 4/8/12mm

- Temperature measurement range (-T Models): -20°C to 550°C (-4°F to 1,022°F)

- Temperature measurement accuracy (-T Models): Max (±2°C, ±2%)

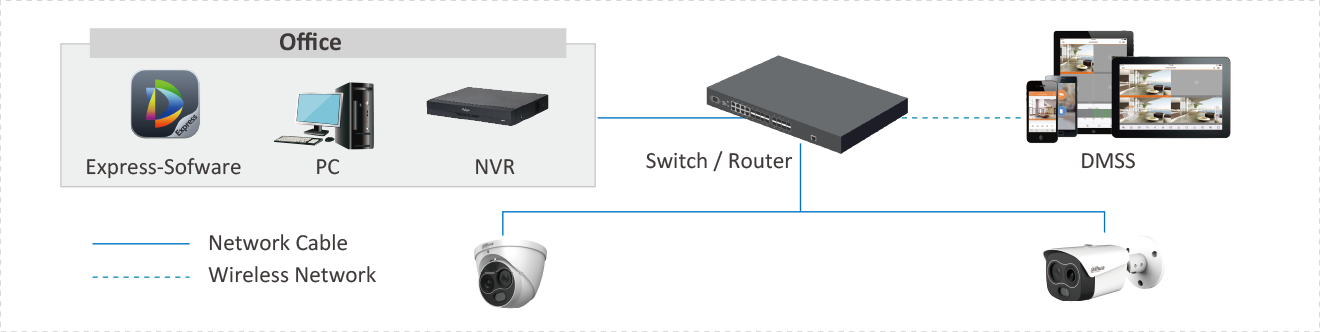

Recommended Solution

Effective Coverage

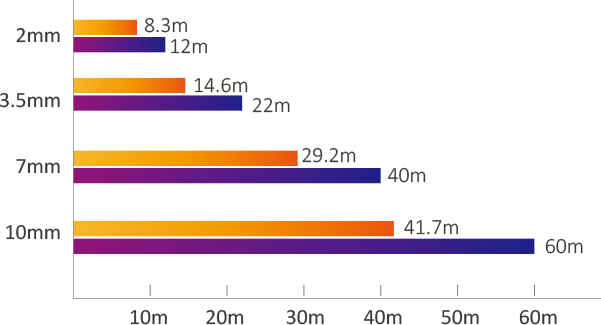

Fire Detection

Fire-source size: 0.2m x 0.2m

Recommended distance testing condition: Anti-jamming, 80 Sensitivity

Max. distance testing condition: Anti-jamming, 80 Sensitivity

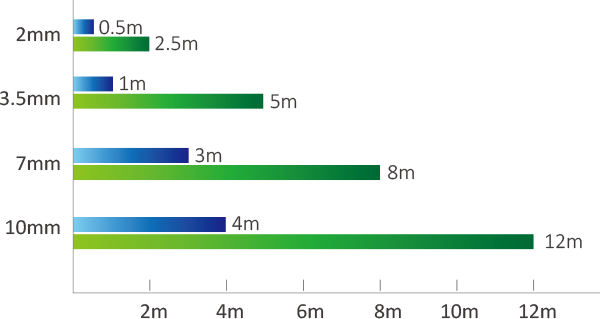

Temperature Measurement

Target size: 0.1m x 0.1m

Min. Distance

Max. Distance

1. Test ambient temperature: 23°C; Relative humidity: < 60%

2. The data is only used to reflect the maximum performance of the camera. The performance of intelligent function depends on the actual conditions on the site